TESTING & QUALIFICATION

Our dedicated Test & Evaluation Center (TEC) rigorously tests our escape systems to ensure a fail-proof exit strategy for the aircrew flying in our seats.

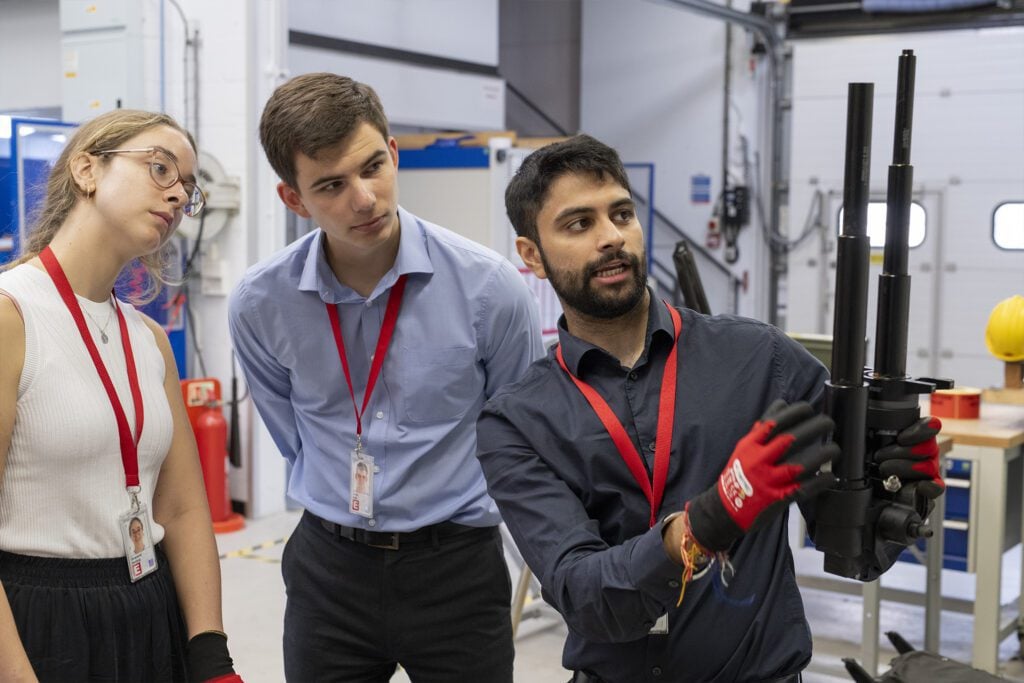

Test & Evaluation Center (TEC)

Martin-Baker has extensive in-house subsystem and full-system test facilities approved to US and NATO military standards. Our facility capabilities extend to structural, environmental simulation and reliability testing which include Human Engineering evaluation.

The TEC is a purpose-built facility, designed and equipped specifically to satisfy the company’s requirements for development, qualification and certification.

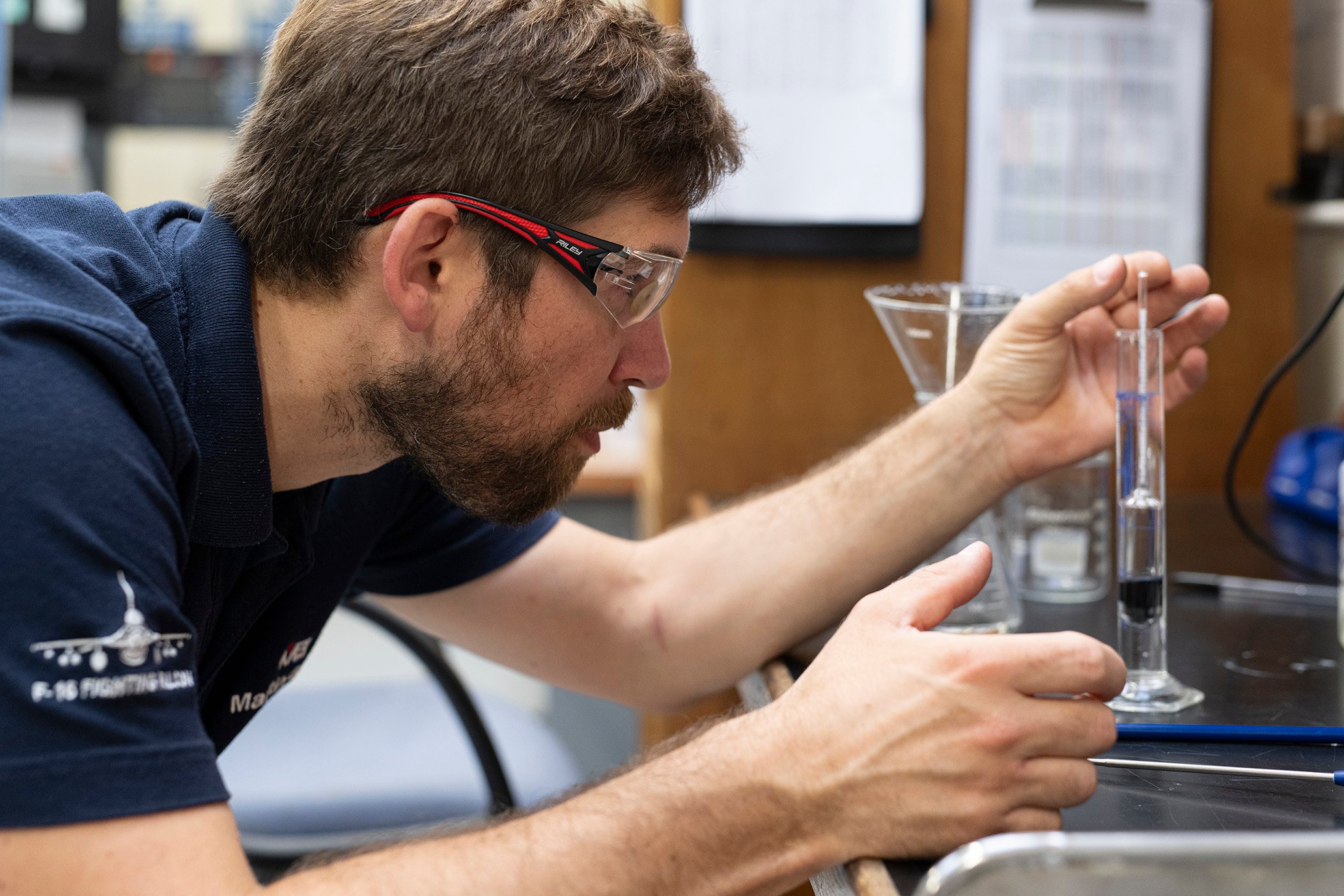

Environmental Testing

Our Denham campus has extensive infrastructure to replicate a full lifecycle of service for our seats. Our dedicated team of over 50 experience engineers and technicians ensure that our products will be fully functional when aircrew need it most.

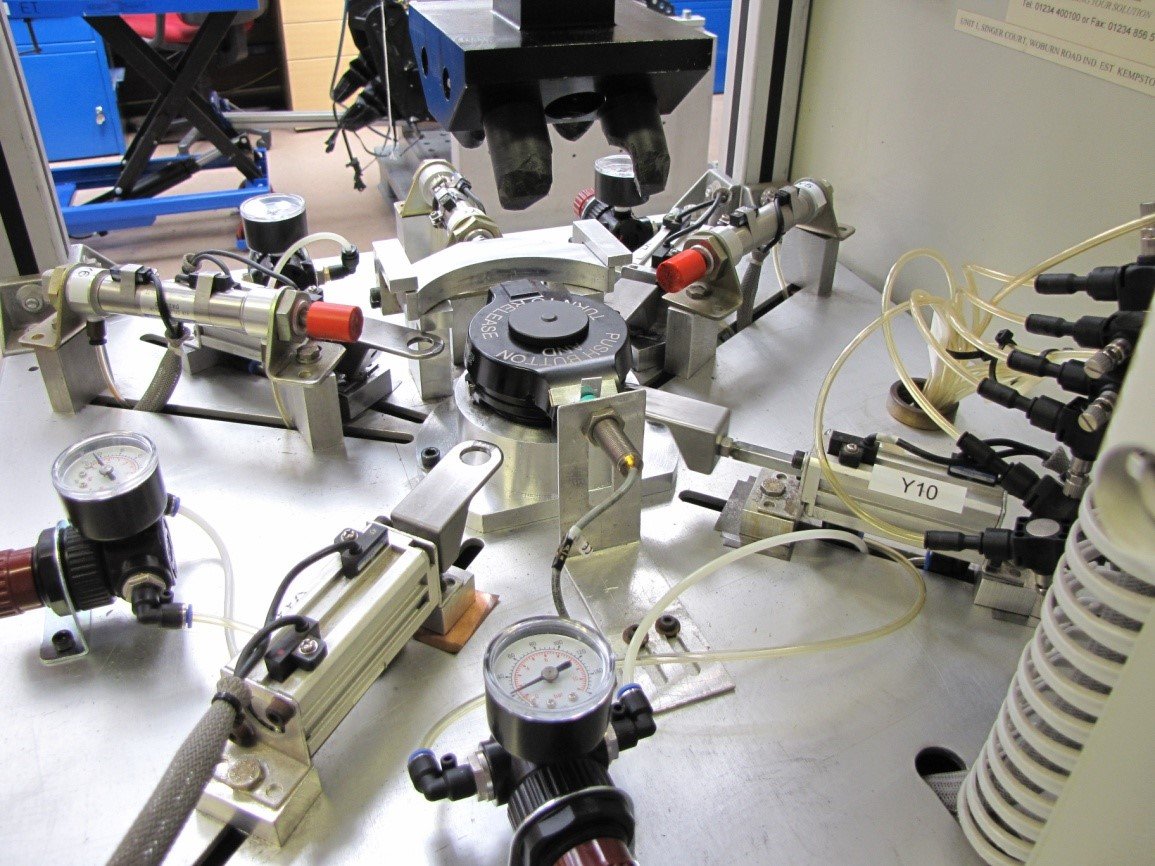

Our capabilities include:

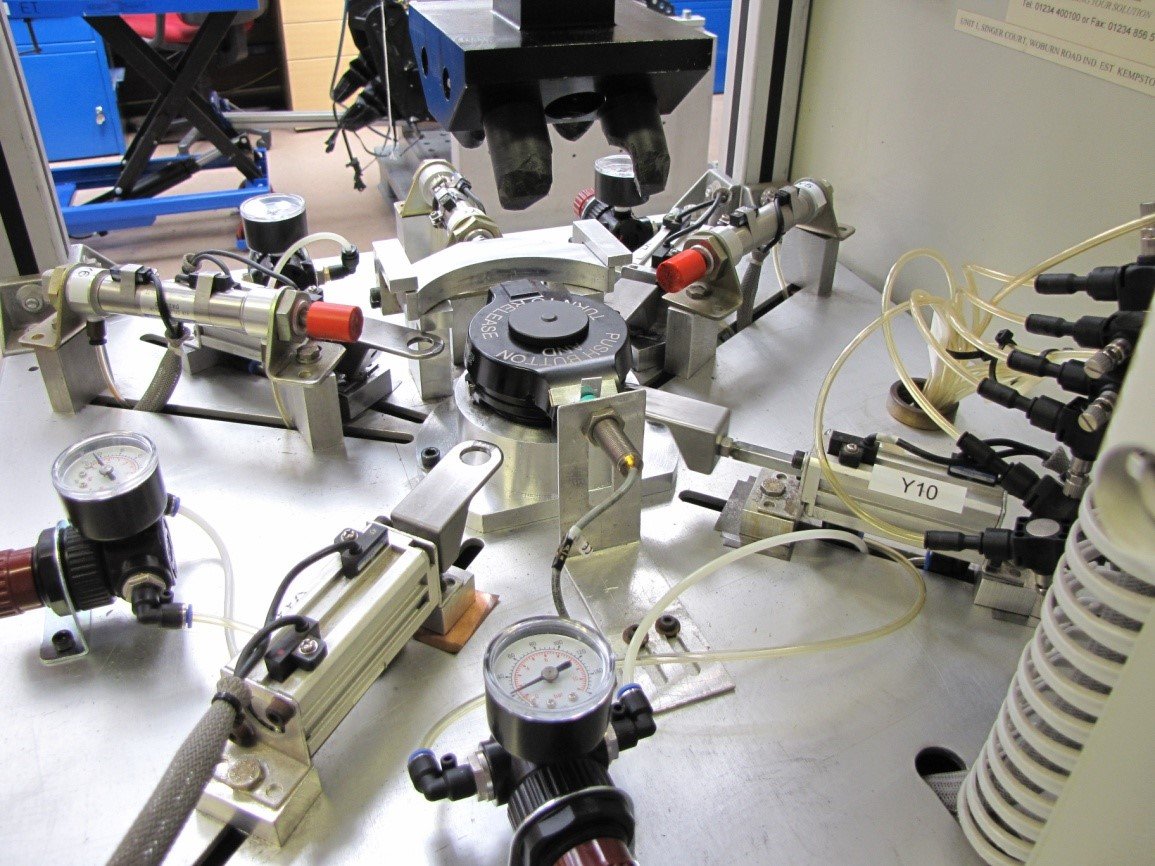

- Combined temperature and thermal shocks with humidity and altitude control.

- Salt mist corrosion cabinets with sulphur dioxide gas injection.

- Free fall mechanical shock testing with universal shock pulse programmer.

- Test assembly vibration within temperature-controlled conditioning chambers.

- 3 vibration test cells available.

- Military standard drop test facility which accommodates free fall testing from a drop height of up to 12m.

- Tensile / Compressive Load Testing (Up to 100kN).

- Structures testing within an adaptable static test frame with load applied via hydraulic rams.

- High-Speed Data acquisition systems with adaptable modular format, providing synchronization between acquired pressure, force and displacement data with high- speed video records.

- Fixture design and in house manufacture.

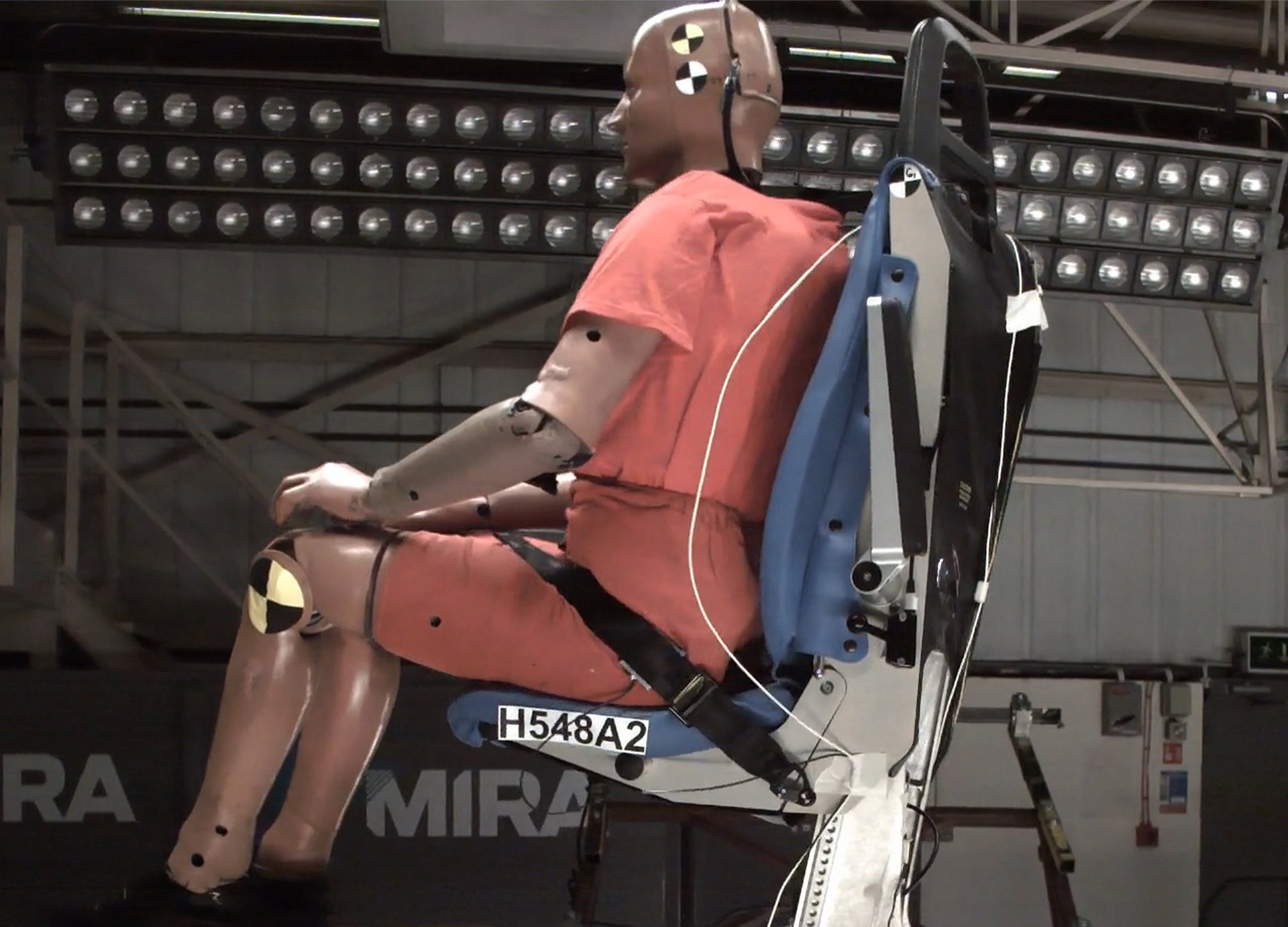

Ejection Seat Testing

Seat test is the final stage of Escape System development and qualification before being certified to be manufactured for service.

To qualify a seat, testing is carried out at the extremes of the aircraft flight envelope to evaluate and verify its performance and safety. This includes testing at speeds between 0 to 600kts at ground level or up to 450kts at altitudes up to 23,5000ft. Occupant ‘nude’ weights can range from 47kg to 111kg (103 to 245lb). With pilot clothing and equipment this can increase to approximately 59kg to 132kg (130lb to 291lb).

Testing is conducted on major sub-systems or at a full system level. This can include anything up to a twin ejection seat with canopy jettison or fracturing. There are a range of test facilities at our Chalgrove (Oxfordshire) and Langford Lodge (Northern Ireland) locations. For ground level testing, Ejection Tower, Catch Net, Zero/Zero pad, Lorry and High-Speed Track facilities are used. For testing at low altitude, Seat test have the use of two Gloster Meteor aircraft. Tests that require higher altitude, bigger safety areas are needed such as the Cape Wrath Range located in the Northwest of Scotland or Cazaux Air Base in the Southwest of France. Parachute testing can also be performed using a specially adapted Parachute Test Vehicle.

Martin-Baker has also collaborated with other international ranges to conduct ejection seat testing, such as Holloman Air Force Base in New Mexico. Any variations of testing for these scenarios are carefully planned, executed, and evaluated, before being reviewed to determine seat readiness.